19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on May 1, 2010 6:55:32 GMT -6

I've always wanted another F-86. My dad and I built a couple when I was a kid, soooooo. I'm going to pick up this little number for kicks. It should be reasonably fast for its size, I can fly it just about anywhere and I'll get my fantasy fix for low bucks. www.hobby-lobby.com/f86_skyblazers_edf_jet_335473_prd1.htmHe, he  |

|

|

|

Post by Gabe on May 1, 2010 8:40:50 GMT -6

Looks like fun, and a fraction of the price of the E-Flite Sabre by the time it's complete.

|

|

19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on May 1, 2010 9:51:19 GMT -6

Yep, it should be fun. I bought it primarily for it's small size. I'd like a much bigger one when I find a suitable spot for takeoffs and landings somewhere close by.

Right now, I can hand toss the little guy at my soccer fields and belly land it so it is ideal for the time being.

|

|

|

|

Post by elkmaster01 on May 1, 2010 10:22:28 GMT -6

19K,,,that looks like fun. I have a couple belly-landers. I beefed them up by using a fiber-glass cloth and a expoxy finishing resin. It really helped on my A-7,,the intake lip was getting beat up pretty bad,,,now it's like a skid-plate,,didn't weight enough to effect it's flying, actually,,the glass finished helped,,less drag.

I did the same thing on my SU-34 since the retracts were not strong enough for my grass runway,,,I put skid-plates on both naccelles and the nose.

|

|

19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on May 1, 2010 13:33:21 GMT -6

Thanks elk, I'll be beefing up those areas. I've heard you can thin epoxy with alcohol and then apply it like paint. That might be enough. Have you heard of that method?

|

|

|

|

Post by elkmaster01 on May 2, 2010 14:01:47 GMT -6

No,,,but I assume it would work. The finishing epoxy resin I got from tower hobbies is just a thin two-part epoxy,,sets up in 2 hours clear. And when you use the fiberglass cloth,,the cloth dissappears,,,,just makes a thicker/stronger skid pad. The epoxy alone has a tendency to crack, especially the 5-minute stuff. Use at least a 30-minute epoxy.

|

|

19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on May 2, 2010 14:14:08 GMT -6

No,,,but I assume it would work. The finishing epoxy resin I got from tower hobbies is just a thin two-part epoxy,,sets up in 2 hours clear. And when you use the fiberglass cloth,,the cloth dissappears,,,,just makes a thicker/stronger skid pad. The epoxy alone has a tendency to crack, especially the 5-minute stuff. Use at least a 30-minute epoxy. Thanks for the info.  How thick is the glass cloth I should be using? |

|

|

|

Post by elkmaster01 on May 2, 2010 17:31:22 GMT -6

This is the stuff I use; www3.towerhobbies.com/cgi-bin/wti0001p?&I=LXK255www3.towerhobbies.com/cgi-bin/wti0001p?&I=LXCX58The cloth is about as thick as t-shirt. Put down a layer of the resin,,then the cloth,,,then another layer of resin,,,,the resin is thin,,like paint. It sets in 2 hours but you should let it set for 12 hours or more. Here's what I did with my A-7. You can tell I have beat the snot out of this plane,,LOL. I have about 50 landings on it since I crashed it and put the cockpit back on with this repair.   |

|

19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on May 3, 2010 6:22:38 GMT -6

This is the stuff I use; www3.towerhobbies.com/cgi-bin/wti0001p?&I=LXK255www3.towerhobbies.com/cgi-bin/wti0001p?&I=LXCX58The cloth is about as thick as t-shirt. Put down a layer of the resin,,then the cloth,,,then another layer of resin,,,,the resin is thin,,like paint. It sets in 2 hours but you should let it set for 12 hours or more. Here's what I did with my A-7. You can tell I have beat the snot out of this plane,,LOL. I have about 50 landings on it since I crashed it and put the cockpit back on with this repair.   Thanks for the links and details. It gave me a flashback to helping a buddy of mine glass his homebuilt sailboat in high school. We must have done an OK job. He was able to sail it back and forth to the Bahamas a few times. And, no, he didn't take me with him. Some Buddy. ;D |

|

19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on May 8, 2010 13:08:26 GMT -6

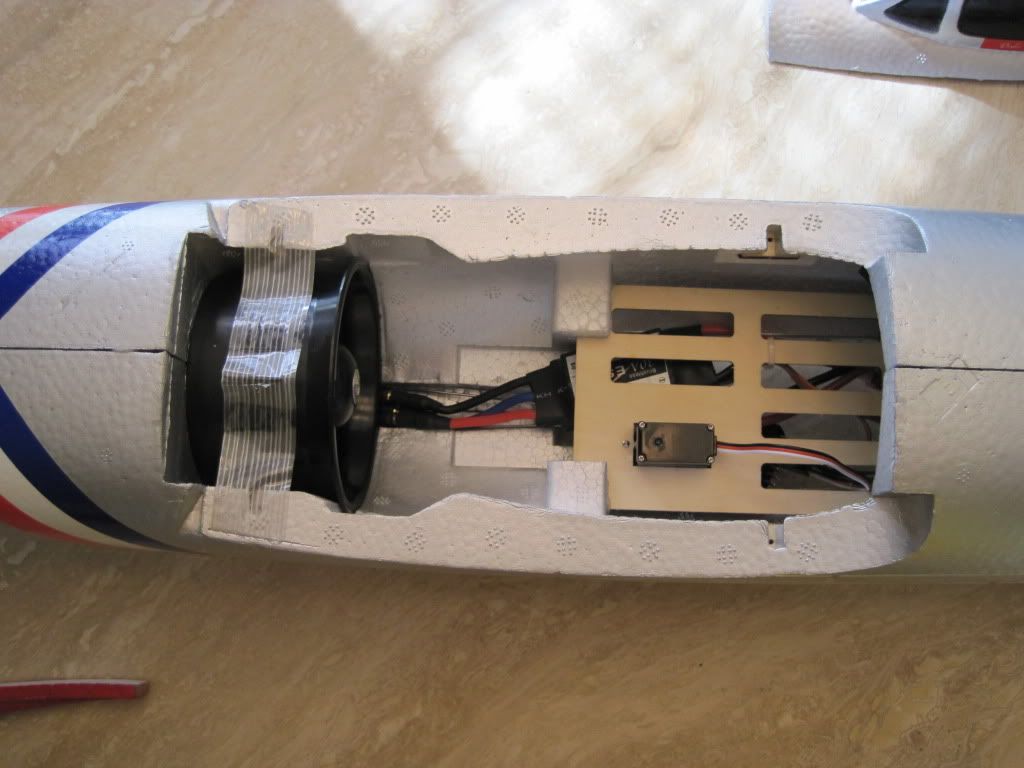

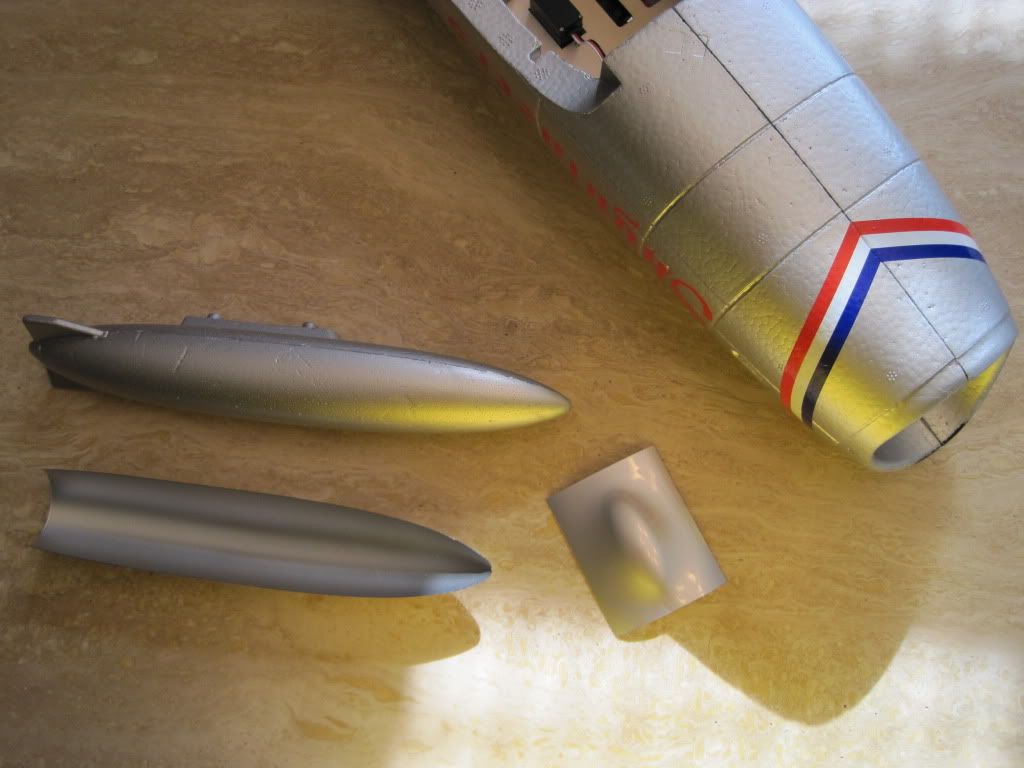

The F86 arrived last night. UPS was really late due to the weather, but they came through. My expectations for an inexpensive ARF weren't real high. I expected the usual quickie approach; marginal workmanship and less than average components. Well, I was pleasantly surprised. Everything was nicely packed and complete with no damaged items. That's always a good start.  Molding of the foam parts is good. The paint is applied well. Not perfect, but darned good for this level of plane. The water slide decals were already applied except the ones for the drop tanks which I discarded because they didn't fit well on the compound curved surface. 3 Servos, 8 or 9g's, Fan/motor, and ESC were pre-installed as are the Deans connectors on both the battery and ESC. "3 ton" two part epoxy was included. If I have any left over I'll glue a couple of SUV's together and see if they can pull apart from each other. ;D This plane looks better in reality than, I think, the pictures indicate.  The very complete pkg. included a 1500 15c battery. I think I'll eventually use a 20-25c.  I was impressed with the fact that the elevators had REAL hinges and that there were seperate control rods and clevises for both sides run from a single servo. The control horns and clevises were not installed. The hardware is a good quality screw in type and both halves lined up for a perfect fit thanks to accurate mounting spots in the foam.  The ailerons are also pre-hinged and the servos were neatly and securely installed. Many of these small EDF's use a single aileron servo and I was happy to see two servos. They even included a "Y" harness in case you aren't running a dual aileron Rx...Which I'm not. There are FG reinforcements running almost the entire length of each wing. Hope that's enough. The foam seems a bit soft for EPO. The good news is that there are 4 screws that holds the wing on.  The 64mm fan with 4300kV motor is located by a groove in the fuse on top and by grooves in the wing on the bottom. I have some concern that the fan may loosen up with use, but I didn't feel epoxying was in order yet and epoxying wasn't called for in the directions.  The drop tanks (landing surfaces) and the nose area are protected by plastic skid plates to be epoxyed in.  The equipment bay is a tight fit. I could barely squeeze in the AR6100e. A better choice would have been a top pin arrangement. The battery strap was installed with a rubber pad to grip the battery. The rubber pad wasn't really functional for its intended use so I added velcro to the battery and to the Rx.  OK, here she is all buttoned up and ready for her maiden. To secure the hatch, a tab in the foam is used that slots into the fuse (I think that will fail so it will need to be beefed up at some point) and a sufficiently strong magnet forward. I've added a few clicks of up elevator for the hand launch until I see how the first few launches go. I'm really looking forward to flying this plane. It holds so many great memories for me as a kid building and flying the beautiful F86's with my dad. This one's for you dad.  |

|

19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on May 9, 2010 11:29:57 GMT -6

The weather was gorgeous this AM so I went out to maiden the F86. The soccer field was empty. Thank you mothers everywhere.  The hand launch went well. I launched from a slight rise over the soccer field which gave the plane some room to drop. That was a good thing because I forgot to put the few clicks of up elevator in I had planned on  . I gave it a fairly good toss, I didn't want to over do it, but in the future I'll toss it harder. The plane dropped about 4' before the fan generated flying speed. I pulled up and she went into a good scale like climb out. I'm sure I was smiling at this point. ;D I was still at full throttle and once it got going it started moving quickly. I slowed it down some to check the controls. With no trim it flew straight as an arrow. I banked it around back towards me an pushed the throttle up full on. I'm guessing it hit about 55-60 top end which is more, or less, what I was hoping for. I did a series of basic maneuvers. Rolls were fast and crisp. Turns were precise and the 86 always went exactly where it was pointed. Now I was getting a really big smile going. ;D The flybys were great. Some I did low and fast and others at about 50% throttle. I only flew a little over 4min.s which, after checking the battery, should be about 2 thirds of the practical flight time. With no specs on the ESC I'm not counting on BEC. I did a practice approach and let it go around one more time at semi low throttle. Low throttle and it stops flying fairly quickly. On the final I cut the throttle 75 yards out and it coasted in to a perfect landing on the drop tanks.  Post flight inspection produced zero flaws. I couldn't be more pleased. This plane is perfect for the semi scale EDF park flyer in this size range. A giant bang for the buck. |

|

akent

Moderator    FIRST 30 MEMBER

I love the 500!

FIRST 30 MEMBER

I love the 500!

Posts: 2,826

|

Post by akent on May 9, 2010 20:15:03 GMT -6

That's awesome, 19k!

I received mine, too! I agree with everything you say.

Mine didn't fly so nicely, though...

Kent

|

|

19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on May 11, 2010 8:06:14 GMT -6

OK, now the bang for the buck is getting quieter for new Starblazers F-86buyers.

Those guys at HL have now bumped the ARF price to 119 bucks! I only paid $101 9 days ago and Kent paid 111 a few days later. And, the airframe only kit went from 59 to 89. I wish I'd ordered a spare airframe right after I got the ARF.

I wonder if they had a price increase from china (I've heard 20-30% increases from china are anticipated by dealers. And, the dealers are quaking in their boots.) or are they just getting a little greedy?

IMO, this is not an economy to be having a 25%-30% increase in prices unless pure economics force you to. And, then you better be ready to see another drop in sales and mounting inventories.

|

|

akent

Moderator    FIRST 30 MEMBER

I love the 500!

FIRST 30 MEMBER

I love the 500!

Posts: 2,826

|

Post by akent on May 11, 2010 17:22:19 GMT -6

I don't understand that at all!!!

90 bucks for the airframe is a huge ripoff, when you can get the whole receiver ready ARF (motor, EDF, ESC, 3 servos, servo extension, control rods, a 1600ma 3s 15c BATTERY, etc.) for 30 bucks more!

To go from a hundred bucks to 120 is not ludicrous, but it is serious. I mentioned at the field that mine was 110 for receiver ready, INCLUDING a battery, and a few guys thought I was kidding.

I still think 120 bucks for this jet is a very good deal. I am even impressed with the electronics!

I would like to know how they painted this jet. It is a beautiful paint job! There must be a trick...

Kent

|

|

19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on May 20, 2010 17:06:51 GMT -6

I managed to stuff the Sabre in the turf out at the soccer field. No excuses, just got a bit too fancy too low. The usual humbling experience. ;D

The good news is that the only real damage was to the plywood mounting board for the electronics and the elevator servo. The servo was so stripped and when I turned the arm it was like there were no gears in it at all. Never had a servo that stripped before. ;D

I pieced the plywood back together, fixed a small crack in the fuse, blew out a few wrinkles in the nose foam with the blow dryer and put in a new servo.

So, we're good to go again tomorrow. Maybe I'll be more careful, or maybe I won't. It's hard not to get a little crazy with this thing. LOL ;D

|

|