19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on Sept 6, 2010 7:54:04 GMT -6

In anticipation of winter coming on in a few months I have a couple of builds that I've been thinking about for a while and need to get done. My focus  is going to be a Clipped Wing Super Cub using the foam from a PKZ SC as a starting point. Objectives: I will build it with four season flying in mind utilizing standard cub wheels, Tundra wheels, Skis and Floats. I want plenty of power for water take offs and to deal with big wind and produce good aerobatic capabilities. The CWSC, I hope, will hang on the prop and do Knife Edge, Torque Rolls, etc. with any of the gear systems in place and still float in on landings like a stock SC. Maybe I'm dreaming ;D I'll cut about 7" out of the center of the wing and use a 5mm CF tube to join the remaining 41". I will cut deep ailerons almost the entire length of each wing. The wing will have zero dyhedral. Power will be a 10, up to, maybe, a 15, brushless mounted on a Custom RC CNC motor mount, 40A SBEC ESC and up to a 2200 30 C pack. I'm going to use 2 & 3 blade props yet to be determined. I'm going to doll her up with a special blue and yellow paint job. It's going to be fun and a little bit different. Just like me, or so they tell me.  |

|

|

|

Post by fireguzzi on Sept 6, 2010 8:25:01 GMT -6

Definitely interested in this. Can't wait to see how it goes.  |

|

19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on Sept 6, 2010 9:41:14 GMT -6

I'll keep you up on the progress fire with some pics to be posted soon.  |

|

19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on Sept 15, 2010 8:35:52 GMT -6

Here's a tentative list of components.

Quantity Description Part #

Power system

1ea. CustomRC Motor Mount CRCA 1021

1ea. Eflite Power 10 Motor EFLM4010A

1ea. Eflite 40A ESC EFLA1040

1ea. Tenergy 2200 25C LIPO TNG25C22003SE

1ea. Eflite 5mm Prop Adapter EFLM1925

1ea. MAS 11x6 Prop MS1160NE

Servos

2ea. SV80 long wire Servos PKZ1081

2ea. Elev. & Rud. Servos PKZ1060

Radio System

Rx

1ea. 2.4 multifunction Rx HBZ7357

Optional Rx

1ea. 2.4 AR6110 SPMAR6110

Tx

1ea. 2.4 DX5e SPM5500

Optional Tx

1ea. 2.4 DX6i (Tx only) SPMR6600

Landing Systems

1ea. 1” Dubro minilite Tail wheel DUB100MW

1set 2 ½” Dubro “Tundra” wheels DUB250SL

1set Dubro Parkflyer Skis DUB830

1set Hobbyzone Floats HBZ7390

Super Cub Foam and Misc. accessories

1ea. Fuselage HBZ7385

1ea. Wing HBZ7120

1ea. Tail set HBZ7125

1ea. Cowling HBZ7126

1ea. Landing Gear Set HBZ7106

1ea. Decals HBZ7127

1ea. Special Graphics

1ea. 5mm CF Wing Spar

1ea. Custom CF Wing Struts

|

|

|

|

Post by Gabe on Sept 15, 2010 11:12:28 GMT -6

The lower the kv of the motor, and the more poles, the higher the torque will be. This is great for turning larger props such as your 11x6, but the trade off will be higher amps. I'm guessing though that the 40 amp esc should be fine. Looks like a great setup!

|

|

19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on Sept 15, 2010 14:49:33 GMT -6

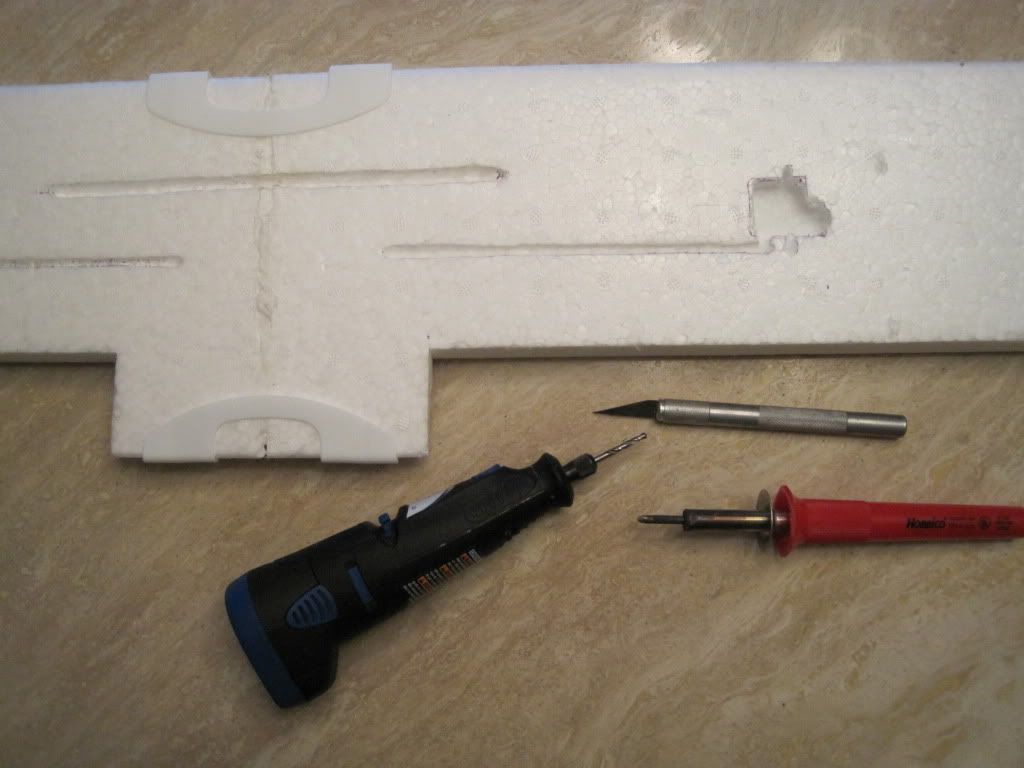

Thanks for your comments Gabe. Here's a few pics of the clipped wing part of the mod.  The 7" cut out of the center of the wing goes nicely with a fine toothed hobby saw.  The modified 41" wing was Gorilla Glued in a flat, zero dyhedral, position. I've layed out the CF spar location, servo pockets and wire lead cut outs and ailerons. The ailerons are about 2" by 14". |

|

19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on Sept 21, 2010 8:07:37 GMT -6

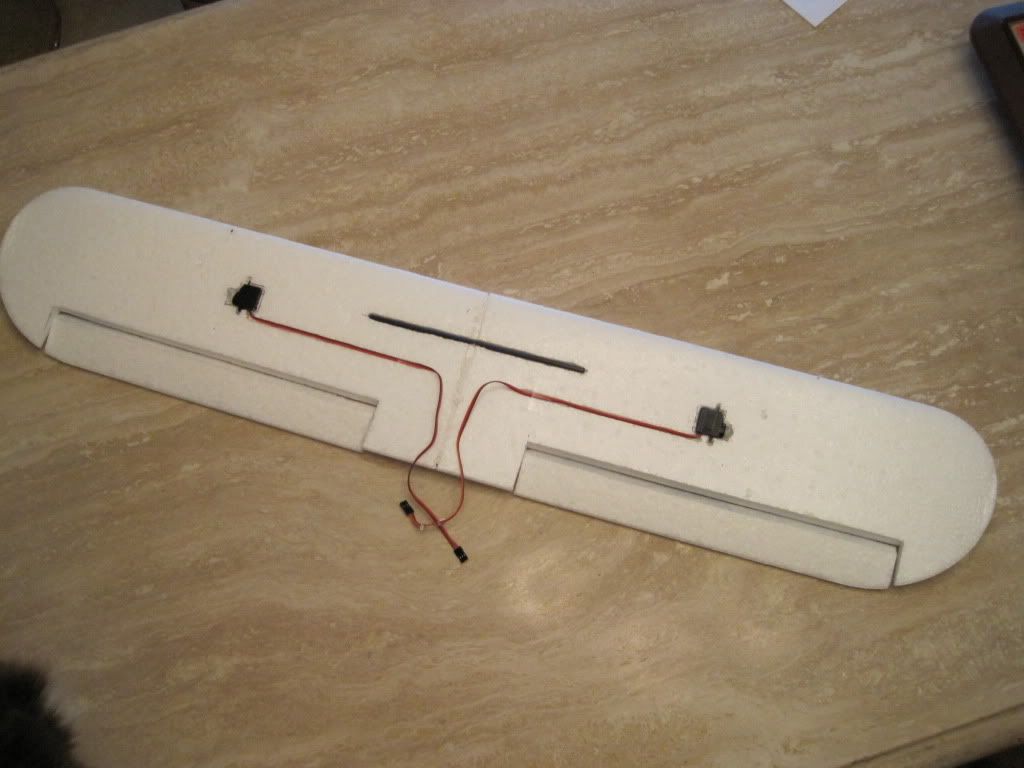

I cut the ailerons out and beveled the inside of the aileron about 30 degrees.  I use a steel rule to keep the cuts straight and a very sharp hobby knife to make the cuts.  The aileron is flipped over in this photo. I do the bevels with a fresh single edge razor since I'm cutting across the foam cells at an angle and anything duller starts to rip the foam cells. I mark off a line on each side of the foam that approximates the 30 degree angle and keep the blade in line on each side as I cut. With care, I end up with a fairly straight cut. I leave about a 3/16" deep foam shoulder on the wing side of the aileron so a variety of hinge methods can be used including; CA hinges, tape or plactic hinges. |

|

akent

Moderator    FIRST 30 MEMBER

I love the 500!

FIRST 30 MEMBER

I love the 500!

Posts: 2,826

|

Post by akent on Sept 22, 2010 17:32:01 GMT -6

That's going to be a beast of a Super Cub!

The Eflite power 10 is very strong!

That's what I ran in the Ultimate. Unlimited vertical.

That's going to be FUN!

Kent

|

|

19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on Sept 23, 2010 7:29:49 GMT -6

My last SC had a 480 motor and it was a very good performer. You're right kent, moving to the 10 should make it wild. If it doesn't; there's always a 15    Servo pockets: I cut the basic rectangular shape with a hobby knife to give a smooth edge and then used a Dremel cutting tool to remove the foam to the proper depth to make the servo flush with the wing's surface. Grooves: I used a cheap soldering Iron to cut the grooves for the CF wing spar and the servo wires. I used the metal rule to control the melt.  Next, I dry fit all the components. Then, I washed all the foam with soapy water and scrubby sponge and rinsed it to remove the mold release on the foam's surface. This ensures that the paint will adhere to the foam. At least I hope it will.  |

|

|

|

Post by Gabe on Sept 23, 2010 8:19:06 GMT -6

Killer job 19K! Very clean and precise.

|

|

19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on Sept 25, 2010 8:34:45 GMT -6

Thanks, Gabe. I fit the CustomRC motor mount to the Power 10 motor. I say fit, because I needed to remove a bit of material from the shaft hole in the mount to accomodate the power 10's shaft retainer collar. I used the dremel drum grinder to remove enough material for clearence.   The motor mount's mounting holes are correctly spaced to match the pre-drilled holes in the firewall. The overall length of the motor and mount is about 1/4" longer than stock. No problemo. Just added some new mounting holes in the cowling. |

|

|

|

|

|

Post by Gabe on Sept 25, 2010 18:11:46 GMT -6

Looking good. This is a great build log!

|

|

19000rpm

Moderator    FIRST 30 MEMBER

FIRST 30 MEMBER

Posts: 5,183

|

Post by 19000rpm on Sept 30, 2010 12:57:08 GMT -6

The ailerons are done.   I used the hardware from the PKZ P-51  Due to the short length of the screws on the control horn backing plate I did a little counter sinking of the plate. |

|

|

|

Post by Gabe on Sept 30, 2010 13:37:49 GMT -6

Looks like a clean job - as always. Nothing like taking your time and doing the job right.

|

|